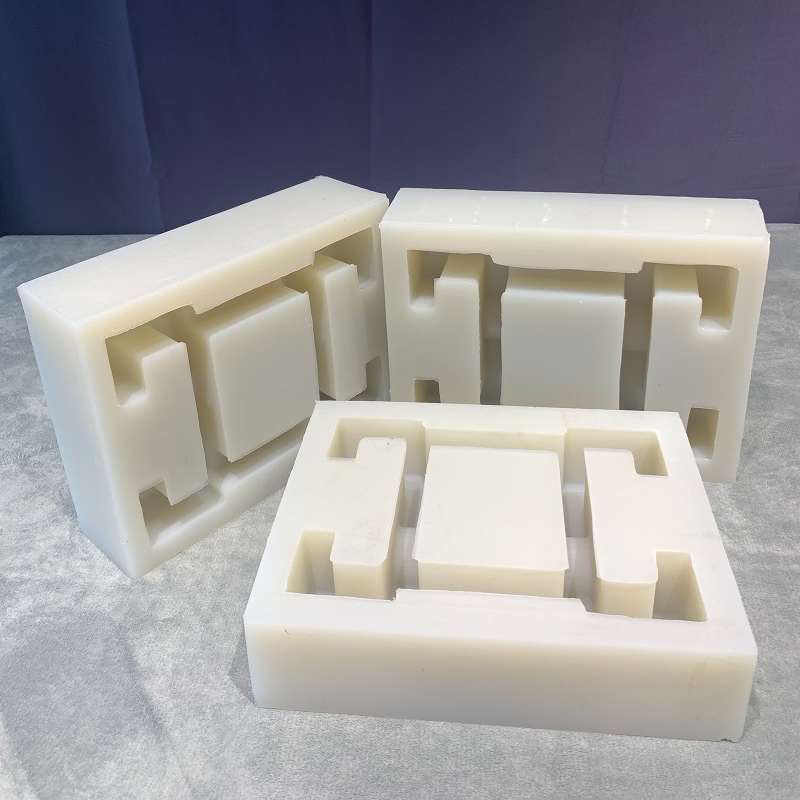

Vacuum casting, which is also termed as silicone moulding can be considered a flexible method of manufacturing used to produce small to medium batch sizes of high-quality plastic parts. In this process, liquid silicone rubber encapsulates a master pattern that is usually made through 3D printing or CNC machining to create the mold. Subsequently, when the silicone cures, the master pattern is taken out leaving behind a cavity with exact geometric configuration as in the initial part. Vacuum pressure then fills the mold with molten resin that flows smoothly and covers all intricate details of the mold. After the resin hardens, it is demolded and finished parts are further processed according to requirements if required. Vacuum casting has several advantages such as fast turn-over times, cheap tooling compared to injection molding and complex geometries with small features on them. It’s commonly used in industries like automotive, aerospace, consumer goods and prototyping where there is demand for small batches of high quality products.

Overall vacuum casting offers many benefits for producing high-quality plastic parts at low cost making it a versatile and economical manufacturing process. Its quick turnaround time combined with excellent surface finish gives it an advantage over other methods hence making it suitable in numerous industries like automotive, aerospace as well as consumer goods, etc that require complicated designs and perfect finishes.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

Vacuum casting offers lower tooling costs, rapid turnaround times, and the ability to produce small batch sizes economically. Additionally, it accommodates intricate geometries and complex part designs effectively.

Yes, vacuum casting supports a wide range of casting materials, including polyurethanes, epoxies, and silicones, allowing for the production of parts with varying mechanical, thermal, and aesthetic properties.

Vacuum casting projects typically have a turnaround time of days to weeks, depending on factors such as part complexity, batch size, and material selection. This rapid turnaround enables quick iteration and validation of designs.

Vacuum casting utilizes flexible silicone molds, which accurately replicate the geometry of master patterns, ensuring precise reproduction of intricate details and complex features in the final parts.