A distinguishing feature of CNC machining services is their ability to accommodate a diverse range of materials, from commonplace metals like aluminum and stainless steel to exotic alloys and advanced engineering plastics. This versatility allows manufacturers to select the most appropriate material for their application without compromising on the quality or complexity of the machined parts. Moreover, CNC services offer flexibility in surface finishes and treatments, enabling customization to meet specific aesthetic preferences or functional requirements. Whether it's a sleek polished surface or a durable anodized coating, CNC machining services provide the means to achieve the desired outcome with precision and efficiency.

At Huilichuang, our CNC machining services are well-known for their precision and accuracy which represents new standards in quality and uniformity throughout the industry. When programming, tool paths are carefully analyzed to ensure tolerances as small as ±0.005mm enabling each machined part to be perfectly matched with the specifications and requirements set by our esteemed clients. Our dedication to precision engineering never changes even if we're given the task of producing intricate aerospace components or critical medical device parts, thus instilling trust on every front of our service provision.

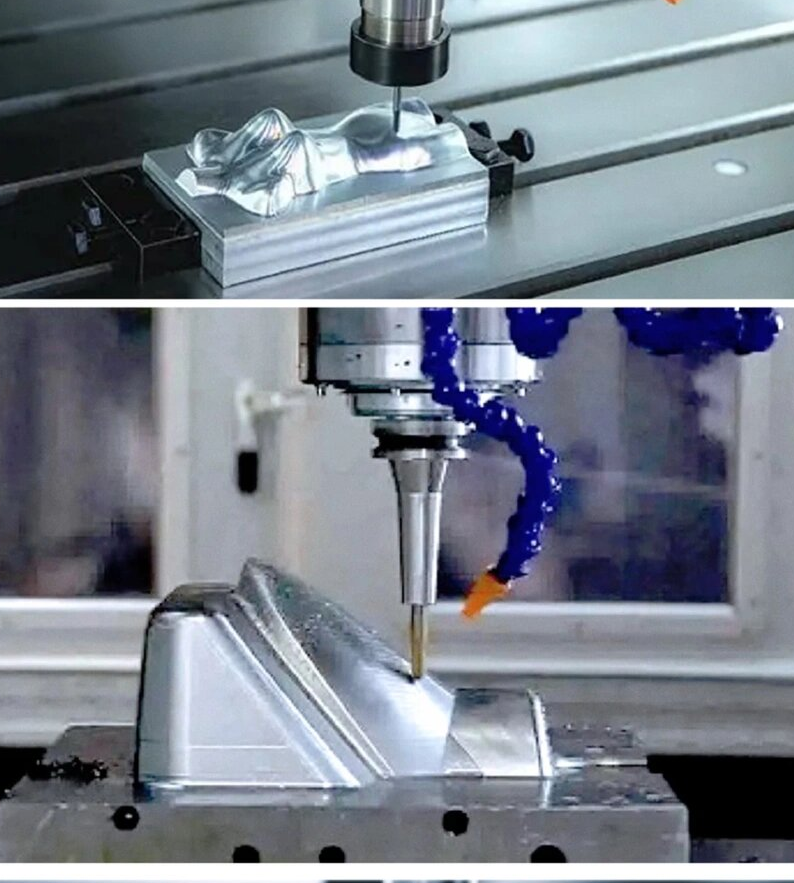

A steady, unswerving commitment to exploring new frontiers in technological advancements and industrialization has been internalized within the very fiber of Huilichuang evident by consistent investments in ultra-modern CNC machining tools and software. We have world class facilities decked with the latest CNC machines as well as the most recent manufacturing technologies that essentially mean we can stretch our imagination to come up with ground breaking concepts for our clients. Always ready to think outside the box, we are looking forward to creating a global revolution in manufacturing through our unmatched CNC machining services that will be proved by time.

One of the many reasons Huilichuang’s CNC machining services are so highly revered is because they are capable of handling a wide range of materials and geometry types thereby presenting diverse options to clients. These services facilitate easy realization of design plans. Our mastery in the field ranges from ordinary metals like aluminum and stainless steel to unusual alloys or engineering-grade plastics, this makes it possible for us to machine almost any material that has strict quality standards. We pride ourselves in being able to handle complex geometries as well as intricate designs, which give room for unlimited creativity and invention as far as product development is concerned.

Huilichuang is a leading manufacturer that offers various types of CNC machining services for a wide range of industries. Our CNC machines represent different levels of competency ranging from prototyping to high volume production and the strictest accuracy and quality in each component manufactured is maintained. We are capable of handling the most complicated machining operations through use of sophisticated equipment and state-of-the-art technology thereby enabling our customers to remain ahead in today’s fast-paced business world.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

CNC machining services can work with a wide range of materials including metals like aluminum, steel, and titanium, as well as plastics, wood, and composites.

CNC machining services offer exceptional precision, with the ability to achieve tight tolerances as low as ±0.005mm, ensuring high-quality and accurate parts.

Yes, CNC machining services excel at producing complex geometries and intricate designs, thanks to their computer-controlled precision and versatility.

Quality control in CNC machining services involves rigorous inspection processes, including dimensional checks, surface finish assessments, and material verification, ensuring adherence to specifications and standards.