As plastic 3D printing technology continues to advance, ongoing research and development efforts focus on enhancing material properties, improving print speeds, and expanding the range of printable materials. Innovations such as multi-material printing, advanced post-processing techniques, and in-situ monitoring systems further broaden the capabilities of plastic 3D printing, paving the way for new applications and opportunities. With its potential to revolutionize manufacturing across industries, plastic 3D printing represents a transformative force in the ongoing evolution of modern manufacturing, driving innovation, efficiency, and sustainability.

At Huilichuang, we are motivated by sustainability and plastic 3D printing is one way to achieve it for the manufacturing sector. Traditional manufacturing methods generate much waste and use a lot of resources as opposed to it which uses less material hence it’s more efficient. We want to minimize our impact on the environment through advanced printing technology and materials that are eco-friendly, while at the same time providing maximum value to our customers. In all our undertakings such as cutting down on material wastes or optimizing energy consumption, we are constantly searching for approaches that will allow us make less pollution on earth without compromising quality or performance of products. With Huilichuang, you can confidently engage in sustainable manufacturing, knowing that you are working with a company that has been responsible towards its environmental duties in its business practices.

The plastic 3D printing has become a force that is reshaping modern manufacturing like no other and at Huilichuang, we take the lead in this revolutionary tide. We have redefined the production landscape across industries by leveraging on the transformative power of additive manufacturing through excellence and innovation. The constraints of traditional manufacturing methods are gone; instead, plastic 3D printing creates immense possibilities for developing intricate designs, complex geometries, as well as customized parts with unprecedented ease and efficiency. At the core of our approach is a commitment to stretching the boundaries of what can be done with plastic 3D printing technology. To ensure that we excel in every project that we undertake, we invest in top notch equipment and embrace a culture of continuous improvement which employs leading-edge printing techniques. Huilichuang has the capability to meet various needs of our clients accurately, reliably and professionally from rapid prototyping of new product concepts to mass production of end-use parts.

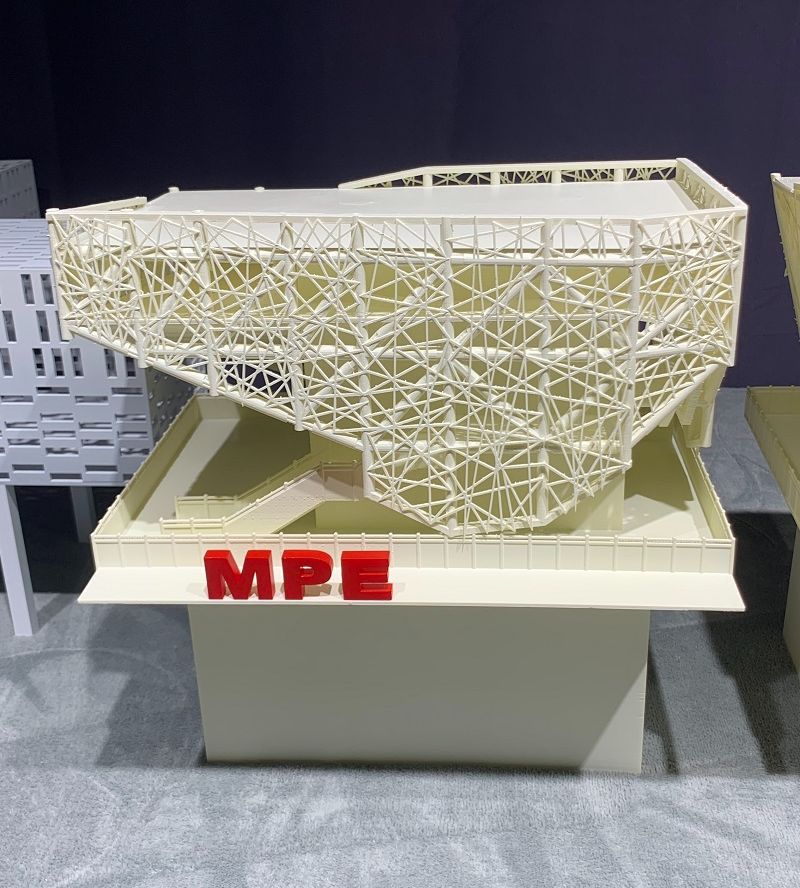

The plastic 3D printing technology that we have at Huilichuang has opened up a whole new world of design possibilities that were formerly unimaginable, and with additive manufacturing’s limitless potential we have a comprehension of how it enhances our designs. We give businesses the ability to move into unknown territories in product design, so that they can be different from their competitors in the market by using our advanced printer and expertise. Our high-tech printer enables us to build intricate lattice structures, lightweight and tough components or geometrically complex shapes such as these and others with an unparalleled freedom of creation than any other 3D-system available today. Huilichuang always works closely with its customers in order to generate detailed production requirements, optimize for manufacturability and perfect the final product to customers’ satisfaction. In today’s dynamic business world, however, companies must depend on collaborative efforts like ours as well as technical knowledge and unwavering commitment to ensure they stay ahead of competition.

One of the most important considerations in business today is cost savings and time, and this is why plastic 3D printing solves them both so well. Plastic 3D printing reduces upfront investment costs through doing away with expensive tooling and setup processes. In addition, its fast lead times allow plastic 3D printing to get products to market early a desirable trait for any company trying to gain a competitive advantage in today’s fast-paced business environment. At Huilichuang we appreciate the need for maximum value realisation by our clients; thus, we provide affordable approaches that do not compromise on quality or performance. Using our advanced printing technology as well as streamlined production processes, we cannot be equaled regarding efficiency and reliability hence businesses can confidently meet their objectives with precision.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

Plastic 3D printing employs a variety of thermoplastic materials, including PLA, ABS, PETG, nylon, and TPU. Each material offers distinct properties such as strength, flexibility, and heat resistance, catering to diverse application requirements.

Yes, plastic 3D printing excels in producing complex geometries and intricate designs with precision and accuracy. Its layer-by-layer additive process enables the fabrication of parts with intricate features, internal structures, and overhangs that are challenging or impossible to achieve with traditional methods.

Plastic 3D printed parts can be finished to achieve various surface textures, including smooth, matte, or textured finishes. Post-processing options such as sanding, painting, vapor smoothing, or surface treatments further enhance the aesthetics and functionality of the parts, catering to specific application requirements.

Plastic 3D printing offers cost-effectiveness by eliminating the need for expensive molds or tooling required in traditional manufacturing. It reduces material wastage and allows for on-demand production, making it a viable option for small-batch production and rapid prototyping.