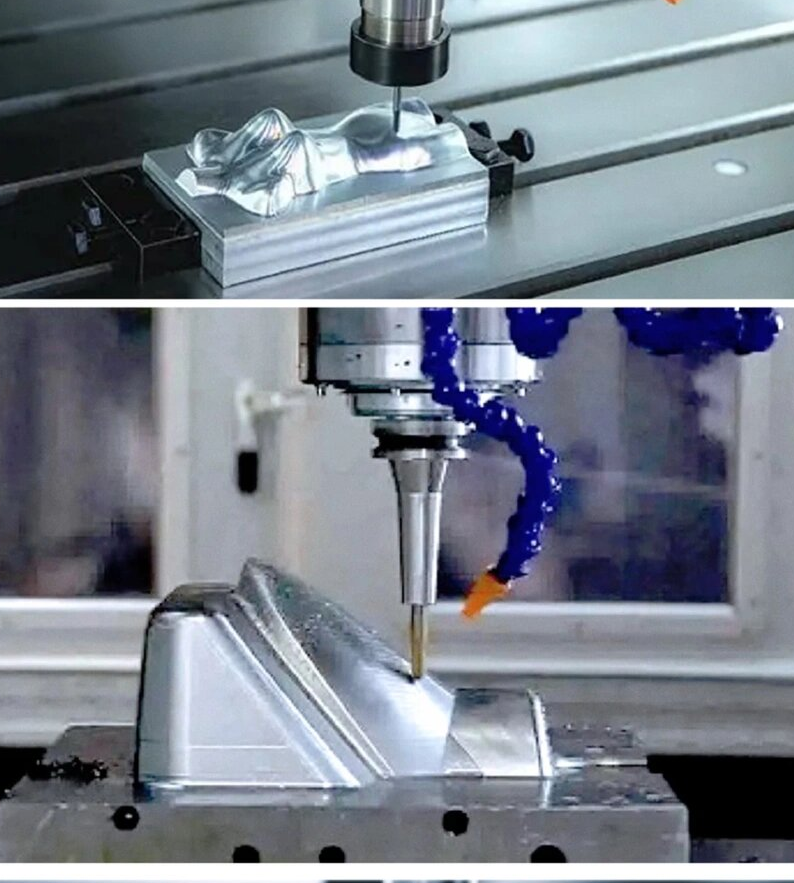

CNC machining services represent the pinnacle of precision engineering, transforming manufacturing processes across industries. By harnessing the power of computer numerical control (CNC) technology, these services offer unparalleled capabilities in producing intricate and highly accurate components from an array of materials, ranging from metals like aluminum, steel, and titanium, to plastics, wood, and composites. The essence lies in the automation of machining processes, where computer programs dictate the movements of cutting tools and machinery with meticulous detail. This automation ensures consistent quality and dimensional accuracy, meeting even the most stringent specifications with ease. From aerospace to automotive and beyond, CNC machining services have become indispensable, driving innovation and efficiency in the modern manufacturing landscape.

In the core of our operating principles, there is an unchanging devotion for quality control that defines our CNC machining services. Right from the moment we receive raw materials to final inspection of finished components, we maintain strict adherence to tight quality and regulatory standards enabling us to achieve topmost excellence in quality and dependability across all our products. Through a number of advanced inspection tools and fine grained protocols of quality control, we converge all these towards ensuring that every component produced by us meets up with the stringent industry requirements thereby giving our esteemed customers an unwavering faith in the soundness of our products.

At Huilichuang, our CNC machining services are well-known for their precision and accuracy which represents new standards in quality and uniformity throughout the industry. When programming, tool paths are carefully analyzed to ensure tolerances as small as ±0.005mm enabling each machined part to be perfectly matched with the specifications and requirements set by our esteemed clients. Our dedication to precision engineering never changes even if we're given the task of producing intricate aerospace components or critical medical device parts, thus instilling trust on every front of our service provision.

The present day dynamic manufacturing environment is all about speed and efficiency and that is where the company’s Huilichuang CNC machining services are specifically designed for. We use the latest automation technologies and toolpath optimization to ensure a more efficient production than anywhere else, which results in shorter lead times but higher throughput without any quality compromise. Our CNC machining services offer high-quality parts delivery on time, whether rapid prototyping or large-scale production is concerned, for these always align with changing customer needs.

We at Huilichuang strongly advocate for the principle of creating partnerships with customers that lead to success for both parties involved. All our experienced engineers and production specialists work together with clients in every stage of CNC machining, starting from initial discussions on designing through to the culmination of manufacturing processes, thereby providing useful tips and knowledge in improving designs in terms of ease of production and cost-effectiveness. By always putting clients first and never stopping at being good enough, we are always hoping to go beyond anyone’s thoughts so that all projects we undertake may have unique worth.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

CNC machining services can work with a wide range of materials including metals like aluminum, steel, and titanium, as well as plastics, wood, and composites.

CNC machining services offer exceptional precision, with the ability to achieve tight tolerances as low as ±0.005mm, ensuring high-quality and accurate parts.

Yes, CNC machining services excel at producing complex geometries and intricate designs, thanks to their computer-controlled precision and versatility.

Quality control in CNC machining services involves rigorous inspection processes, including dimensional checks, surface finish assessments, and material verification, ensuring adherence to specifications and standards.