Plastic 3D printing offers unparalleled design freedom, enabling the creation of complex shapes and intricate geometries that are impractical or impossible to achieve using traditional manufacturing techniques. Unlike subtractive processes like machining, which start with a solid block of material and remove material to create a part, additive manufacturing builds objects layer by layer, allowing for geometric complexity without the constraints of traditional machining. This freedom in design empowers engineers to explore novel solutions, optimize part performance, and consolidate multiple components into single assemblies, leading to lighter, more efficient designs.

The creativity of plastic 3D printing finds its best expression in my company, Huilichuang as we assist companies to do this unlike ever before. This is because it offers an incomparable degree of freedom when it comes to design. When you think about it therefore, there is no limitation to what can be achieved by using plastic 3D printing; any idea can be realized for as long as one is willing to imagine hard enough. As a result of these approaches, the company has the involvement of its customers throughout the entire process from which ideas are from scratch followed by production. Here, we help refine and create our clients’ visions and also work on making them easy to produce by simplifying their manufacturing processes. Huilichuang will collaborate with you and become your creativity’s most tangible embodiment while keeping up with the rapidly changing market realities around you.

One of the most important considerations in business today is cost savings and time, and this is why plastic 3D printing solves them both so well. Plastic 3D printing reduces upfront investment costs through doing away with expensive tooling and setup processes. In addition, its fast lead times allow plastic 3D printing to get products to market early a desirable trait for any company trying to gain a competitive advantage in today’s fast-paced business environment. At Huilichuang we appreciate the need for maximum value realisation by our clients; thus, we provide affordable approaches that do not compromise on quality or performance. Using our advanced printing technology as well as streamlined production processes, we cannot be equaled regarding efficiency and reliability hence businesses can confidently meet their objectives with precision.

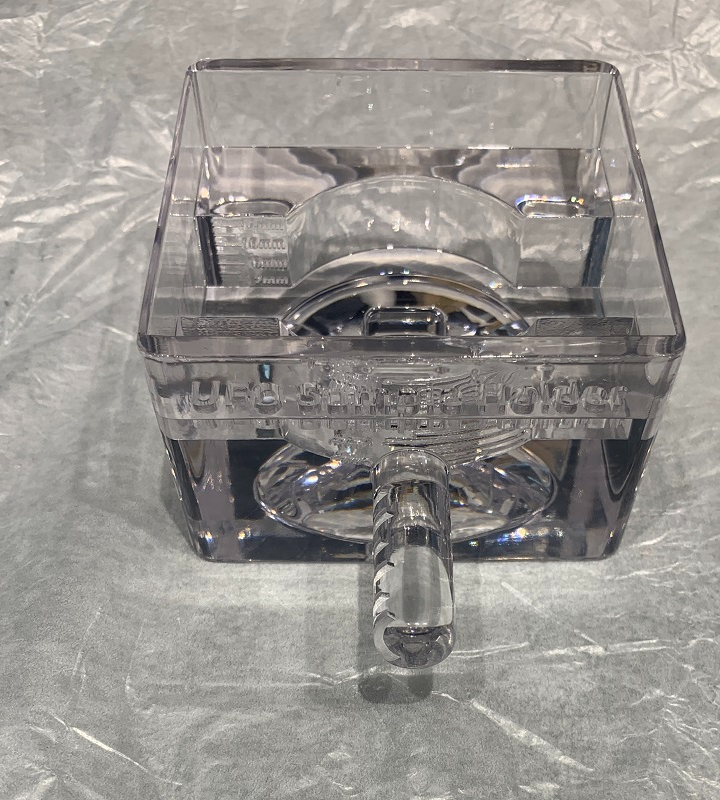

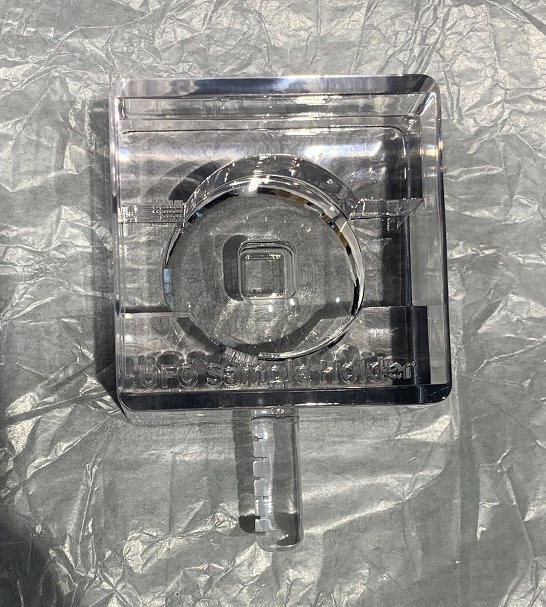

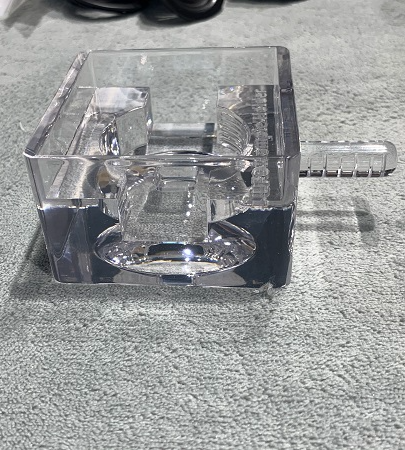

A game-changer for businesses seeking to meet their customers’ unique tastes and preferences in this era of mass customization is plastic 3D printing. There has been unprecedented product customization and personalization at Huilichuang due to plastic 3D printing allowing tailored solutions. It doesn’t matter if it’s bespoke prototype creation, on-demand custom parts production or customized manufacturing services that are being offered, our advanced printing technology makes businesses different from one another in the market and enables them reach their target group more firmly. By offering personalized manufacturing opportunities with Huilichuang as your partner, you can jumpstart differentiation and brand loyalty efforts. We live by these principles whereas taking into account that every project must always surpass a customer’s expectation while being executed with accuracy, precision, integrity and nothing less than excellence as we work. From concept enacting to complete products that speak volume to one’s audience, our aim is achieved through hard work by delivering your vision in every line of facts provided.

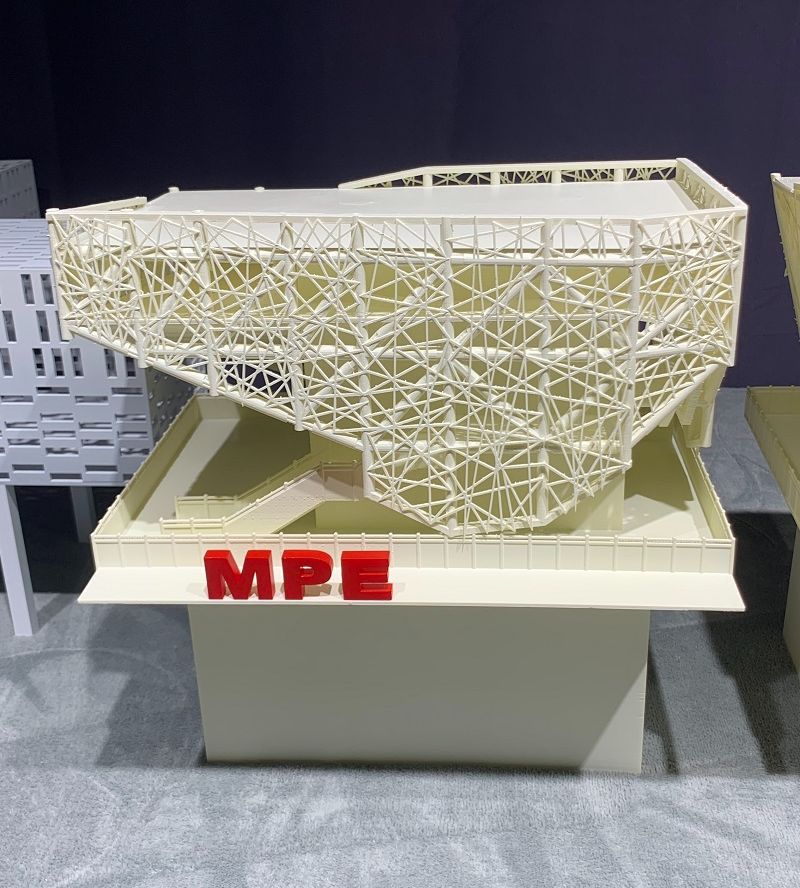

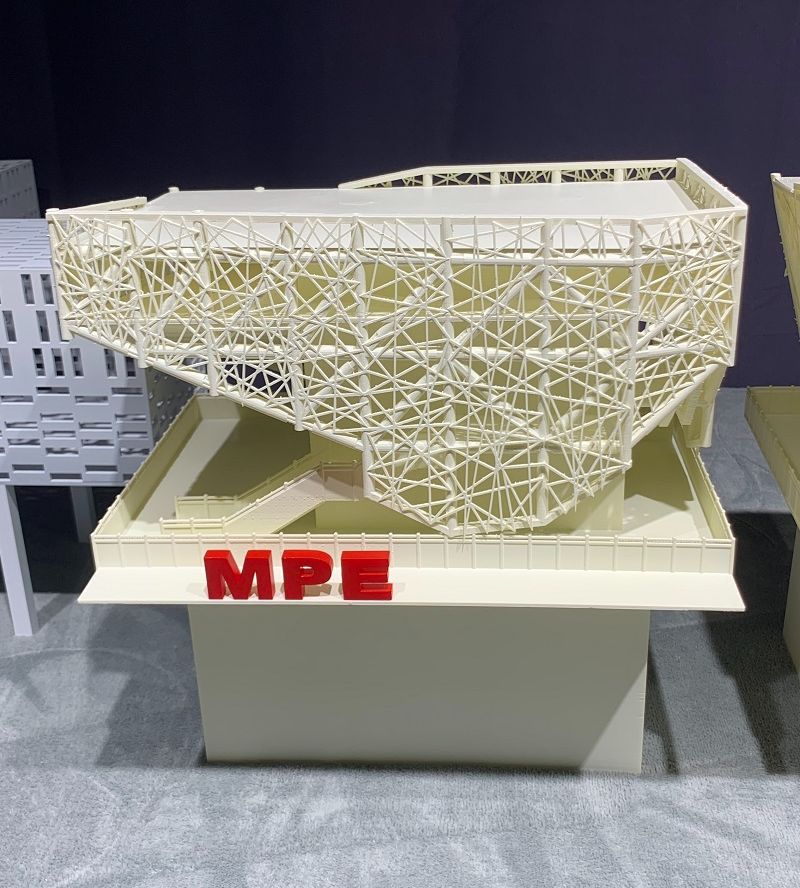

The plastic 3D printing technology that we have at Huilichuang has opened up a whole new world of design possibilities that were formerly unimaginable, and with additive manufacturing’s limitless potential we have a comprehension of how it enhances our designs. We give businesses the ability to move into unknown territories in product design, so that they can be different from their competitors in the market by using our advanced printer and expertise. Our high-tech printer enables us to build intricate lattice structures, lightweight and tough components or geometrically complex shapes such as these and others with an unparalleled freedom of creation than any other 3D-system available today. Huilichuang always works closely with its customers in order to generate detailed production requirements, optimize for manufacturability and perfect the final product to customers’ satisfaction. In today’s dynamic business world, however, companies must depend on collaborative efforts like ours as well as technical knowledge and unwavering commitment to ensure they stay ahead of competition.

UNITECH 3D PRINTING (DONGGUAN) LIMITED, also known as Dongguan Huilichuang 3D Technology Co., Ltd., is a pioneering national high-tech enterprise specializing in comprehensive industrial chain integration services for both addition and reduction materials. Our cutting-edge facility integrates product design, development, and production, including industry application development, alongside the research and production of innovative materials. Situated in Dongguan City, Guangdong Province, our expansive 50,000 square meter plant is equipped with state-of-the-art machinery and offers convenient access to transportation networks.

At UNITECH 3D PRINTING, we specialize in a wide array of services, including 3D printing FDM, SLA, and SLS services, catering to various manufacturing needs. From metal and plastic to resin and nylon 3D printing, our diverse capabilities ensure that we meet the unique requirements of each project. Additionally, our vacuum casting and CNC machining services further complement our offerings, providing customers with a comprehensive solution for their manufacturing needs.

Huilichuang specializes in deep customization, ensuring that each product meets the unique requirements of our customers. From 3D modeling to production, we offer a comprehensive one-stop solution that caters to individual specifications, providing unmatched flexibility and adaptability.

As a high-tech enterprise with our own plant and a wide range of industrial equipment, Huilichuang offers direct manufacturer support throughout the production process. Our in-house capabilities enable seamless communication and collaboration, resulting in streamlined operations and optimized outcomes.

Huilichuang prides itself on providing excellent service through personalized one-to-one interactions and professional experience. Our dedicated team ensures that each customer receives individual attention and support, guiding them through every step of the manufacturing journey with expertise and care.

With industrial-level 3D printing capabilities, Huilichuang delivers products of the highest quality, backed by a stringent quality assurance process. We guarantee the reliability and performance of our products, providing peace of mind to our customers and ensuring their satisfaction with every order.

Plastic 3D printing employs a variety of thermoplastic materials, including PLA, ABS, PETG, nylon, and TPU. Each material offers distinct properties such as strength, flexibility, and heat resistance, catering to diverse application requirements.

Yes, plastic 3D printing excels in producing complex geometries and intricate designs with precision and accuracy. Its layer-by-layer additive process enables the fabrication of parts with intricate features, internal structures, and overhangs that are challenging or impossible to achieve with traditional methods.

Plastic 3D printed parts can be finished to achieve various surface textures, including smooth, matte, or textured finishes. Post-processing options such as sanding, painting, vapor smoothing, or surface treatments further enhance the aesthetics and functionality of the parts, catering to specific application requirements.

Plastic 3D printing offers cost-effectiveness by eliminating the need for expensive molds or tooling required in traditional manufacturing. It reduces material wastage and allows for on-demand production, making it a viable option for small-batch production and rapid prototyping.